SELF CLEANING FILTERS FOR GLUE FILTRATION IN THE TISSUE INDUSTRY

With over three years of research and development, Filtereco has designed a self-cleaning system for glue filtration in the tissue industry, thus eliminating all the problems that can be encountered on the systems of competitors.

Today, there are over 200 plants (FSC-9) built and operating all over the world.

An essential feature is the elimination of the risk of drying of the glue inside the filter, also particularly appreciated is the drying and collection system of the waste expelled from the filter.

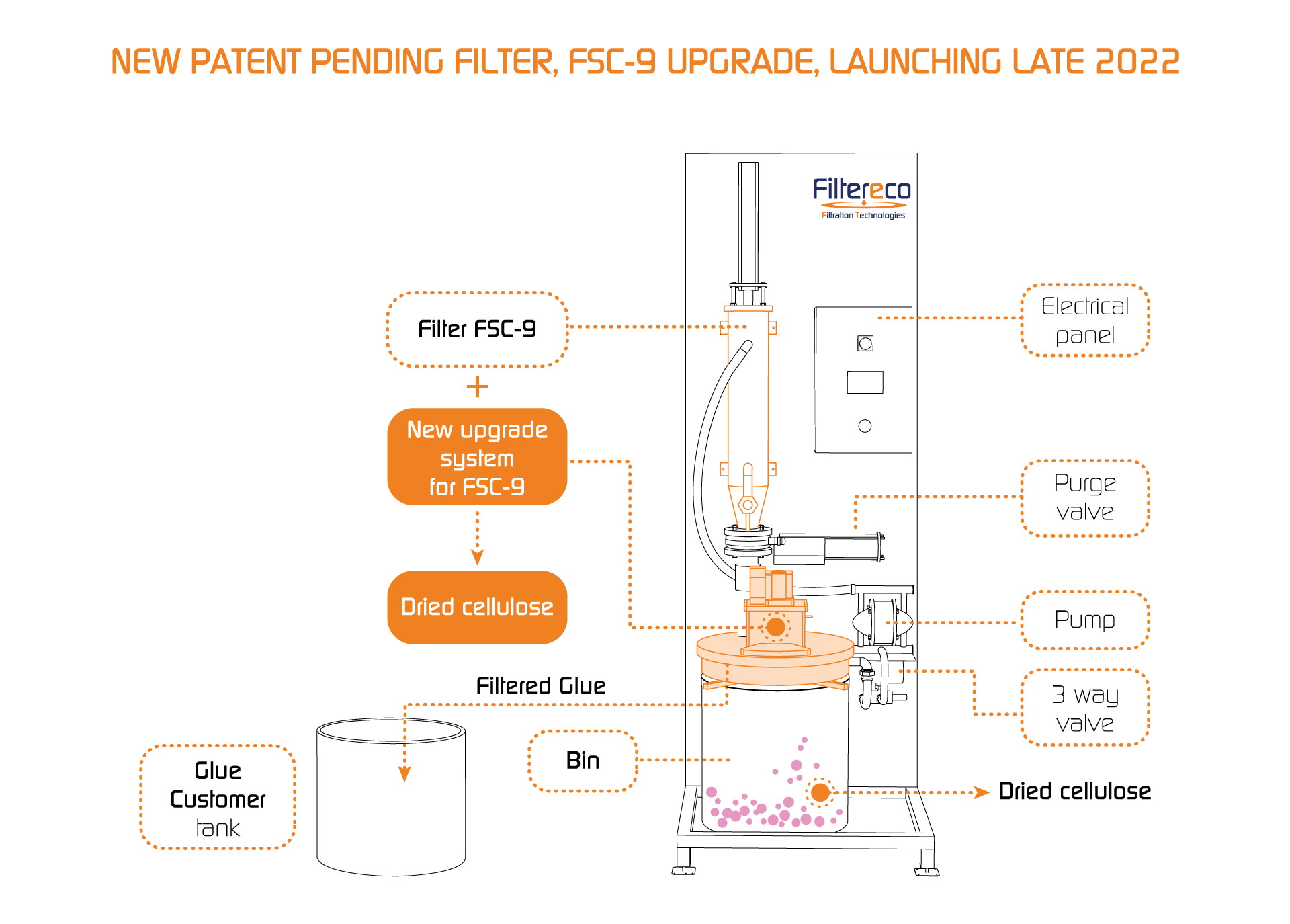

FILTERECO FSC-9 SELF CLEANING SYSTEM FOR GLUE FILTRATION IN THE TISSUE INDUSTRY

An essential feature is the elimination of the risk of drying of the glue inside the filter, also particularly appreciated is the drying and collection system of the waste expelled from the filter.

Normally the system is installed on-bord of the machine of the double-ply gluing line.

The plant is delivered turnkey, simply connect the filter to the glue recirculation tank.

FSC-9 BENEFITS:

- always clean glue pumping

- elimination of incrustations in the pumping pipes

- glue collection tank always clean and free of incrustations

- easy cleaning of the circuit during product change

- totally automatic system and without ordinary maintenance

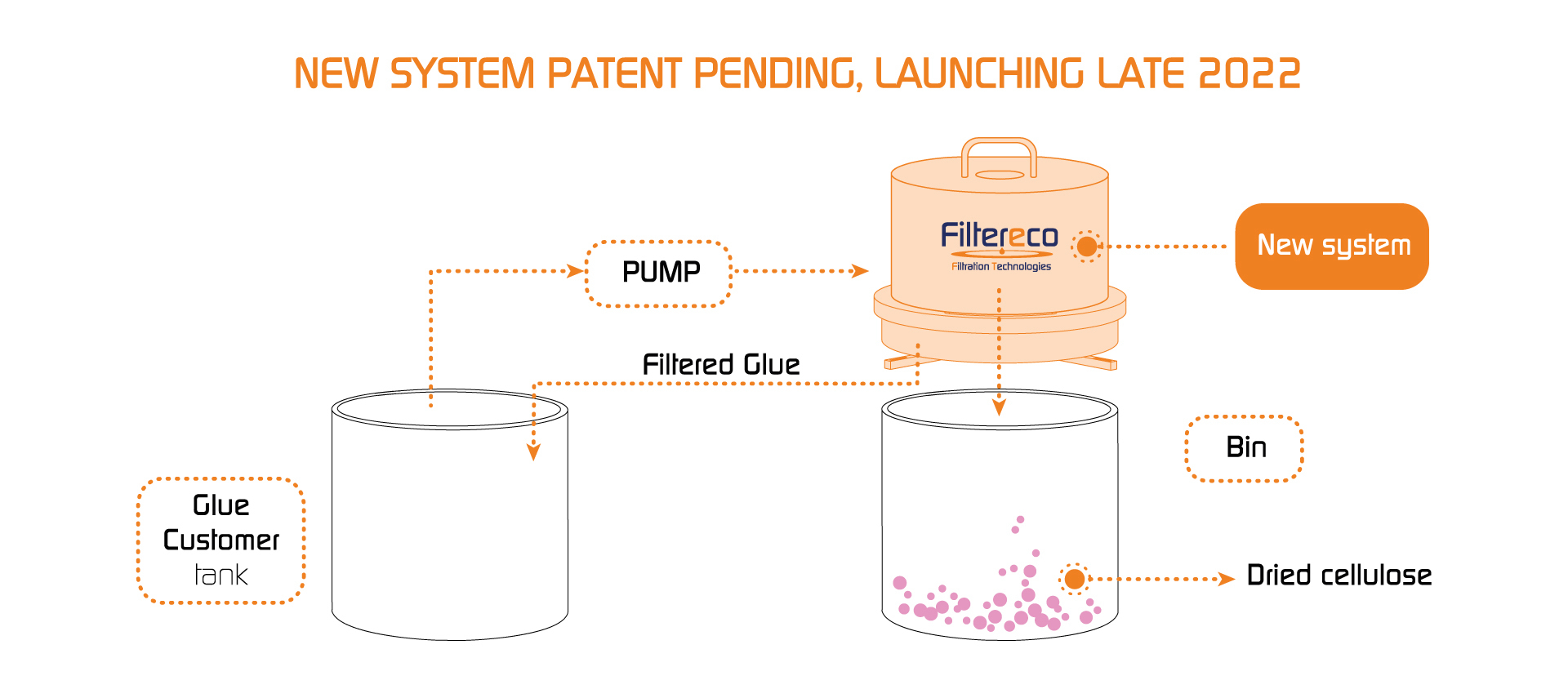

This NEW SELF CLEANING FILTER for glue filtration in the tissue industry, will turn upside down the nowadays filtration way in the paper industry.

Launching late 2022, stay tuned.

NEW BENEFITS

- dried cellulose output

- no filterbag

- no skid

- no purge valve

- no electrical panel

- reduced dimensions

- + benefits FSC-9